▲There are no moving parts in the pipeline, no flow blocking parts, and almost no additional pressure loss during the measurement.

▲The measurement result has nothing to do with the flow rate distribution, fluid pressure, temperature, density, viscosity and other physical parameters. To

▲The range can be modified online according to the actual needs of users on site. To

▲High-definition backlit LCD display, full Chinese menu operation, easy to use, simple to operate, easy to learn and understand. To

▲SMD devices and surface mount are used (SMT circuit has high reliability). To

▲Using a 32-bit high-performance microprocessor has fast calculation speed, high precision, programmable frequency low-frequency rectangular wave excitation, which improves the stability of flow measurement and low power consumption. To

▲All-digital processing, strong anti-interference ability, reliable measurement, high accuracy, flow measurement range up to 150:1

▲Ultra-low EMI switching power supply, suitable for a wide range of power supply voltage, and good EMC performance

▲There are three internal totalizers that can respectively display the forward cumulative amount, the reverse cumulative amount and the difference totalized amount, and there is a non-power-off clock inside, which can record 16 power-off times

▲With RS485, RS232, Hart and Modbus and other digital communication signal output options. To

▲With self-check and self-diagnosis function

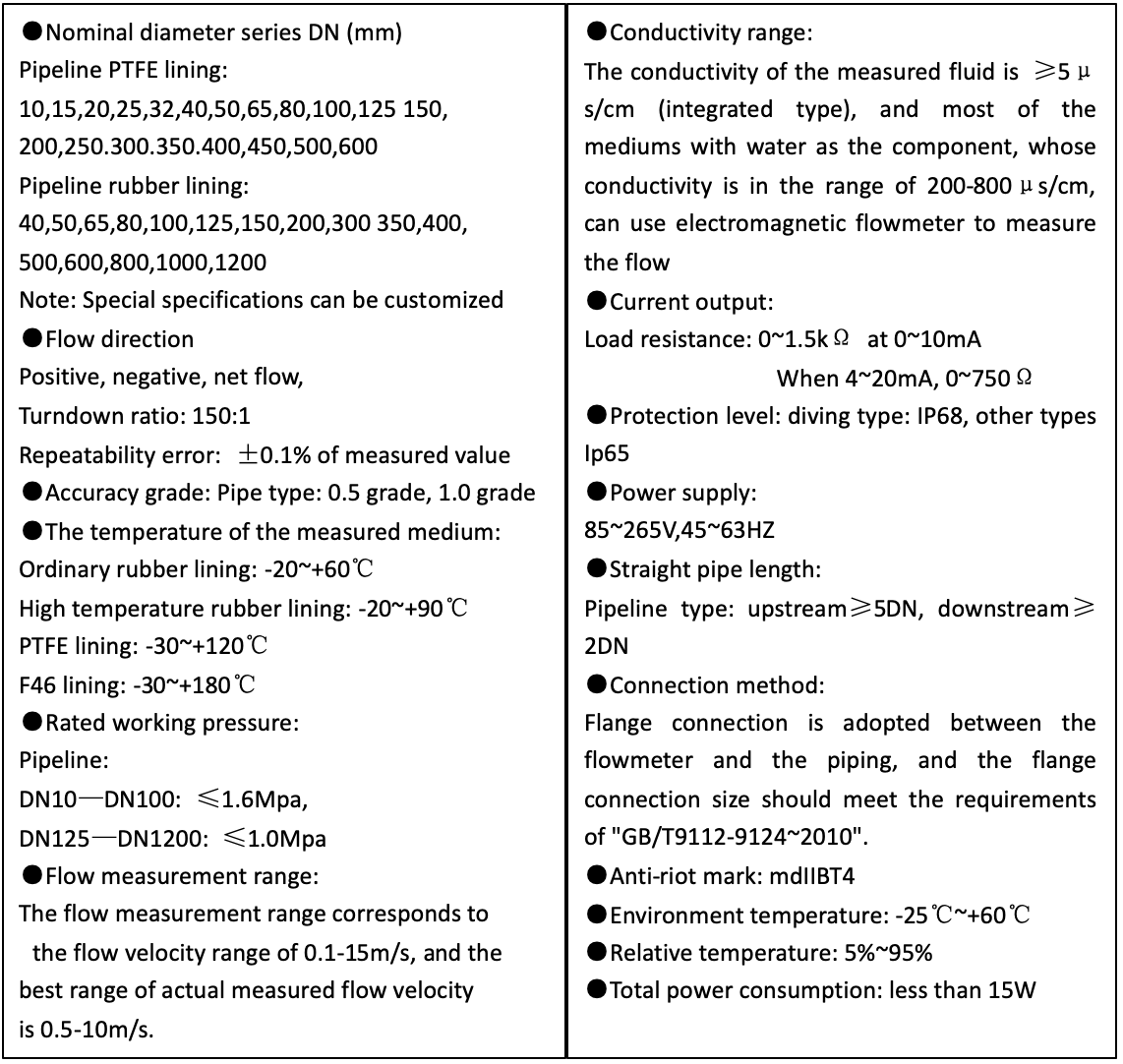

The main technical parameters

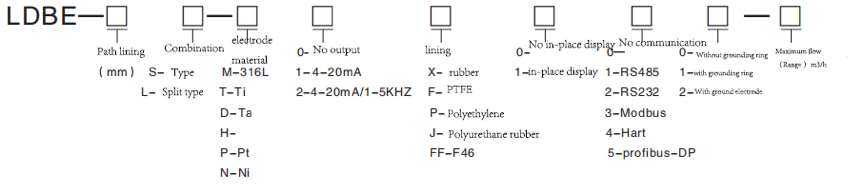

Electromagnetic flowmeter selection

Electromagnetic flowmeter selection instructions

The correct selection of electromagnetic flowmeters is a prerequisite to ensure good use of electromagnetic flowmeters. What kind of electromagnetic flowmeter to choose should be determined according to the physical and chemical properties of the fluid medium to be measured, so that the diameter, flow range, lining material, electrode material and output current of the electromagnetic flowmeter can all be adapted to the measured fluid. The nature and nature and flow requirements.

Measurable fluid

According to the working principle of the electromagnetic flowmeter, the fluid that can be used to measure the flow of the electromagnetic flowmeter must be conductive. Strictly speaking, except for high-temperature fluids, any fluid with a conductivity greater than 5μ/cm should be selected by the corresponding electromagnetic flowmeter. It measures the flow rate. Therefore, non-conductive gases, steam, oil, acetone and other substances cannot use electromagnetic flowmeters to measure the flow rate.

Determination of sensor caliber

The flow rate of the flowmeter is preferably within the range of 0.5-10m/s. At this time, the diameter of the flowmeter can be selected to be the same as the diameter of the user's pipeline. When the flow velocity is lower than 0.5m/s, it is better to increase the flow velocity locally at the instrument part, and adopt the method of shrinking the tube.

Choice of integral type or separate type

Integral type: In the case of a good site environment, the integrated type is generally used, that is, the sensor and the converter are assembled into one.

Separate type: That is, the sensor and converter are installed in different places separately. Generally, the separate type is selected when the following situations occur.

⑴ The ambient temperature or the radiation temperature on the surface of the flowmeter converter exceeds 60°C.

⑵Occasions where pipeline vibration is large.

(3) Severely corroded the aluminum shell of the converter. To

⑷Occasion with high humidity or corrosive gas on site.

⑸The flowmeter is installed in high-altitude or underground debugging inconvenient occasions. To

When ordering, the separation distance between the sensor and the converter should be indicated, generally not more than 200m, and the converter is wall-mounted.