The shell design is light and beautiful

A variety of installation methods and output methods are optional

Using high-precision sensors, has good long-term stability and anti-interference ability

The power supply and output have overvoltage and reverse connection protection functions, and have a high degree of protection up to IP65

This series of sensors is a low-cost temperature sensor specially designed for temperature measurement in the HVAC field. It is suitable for BA systems in commercial buildings and conventional buildings. It has two installation methods: pipeline installation and plug-in installation. Pipeline installation is fixed on the air duct with its own flange or the mounting hole on the shell; the plug-in installation method is fixed on the liquid pipeline through the installation sleeve, which can be used to measure the temperature of the liquid.

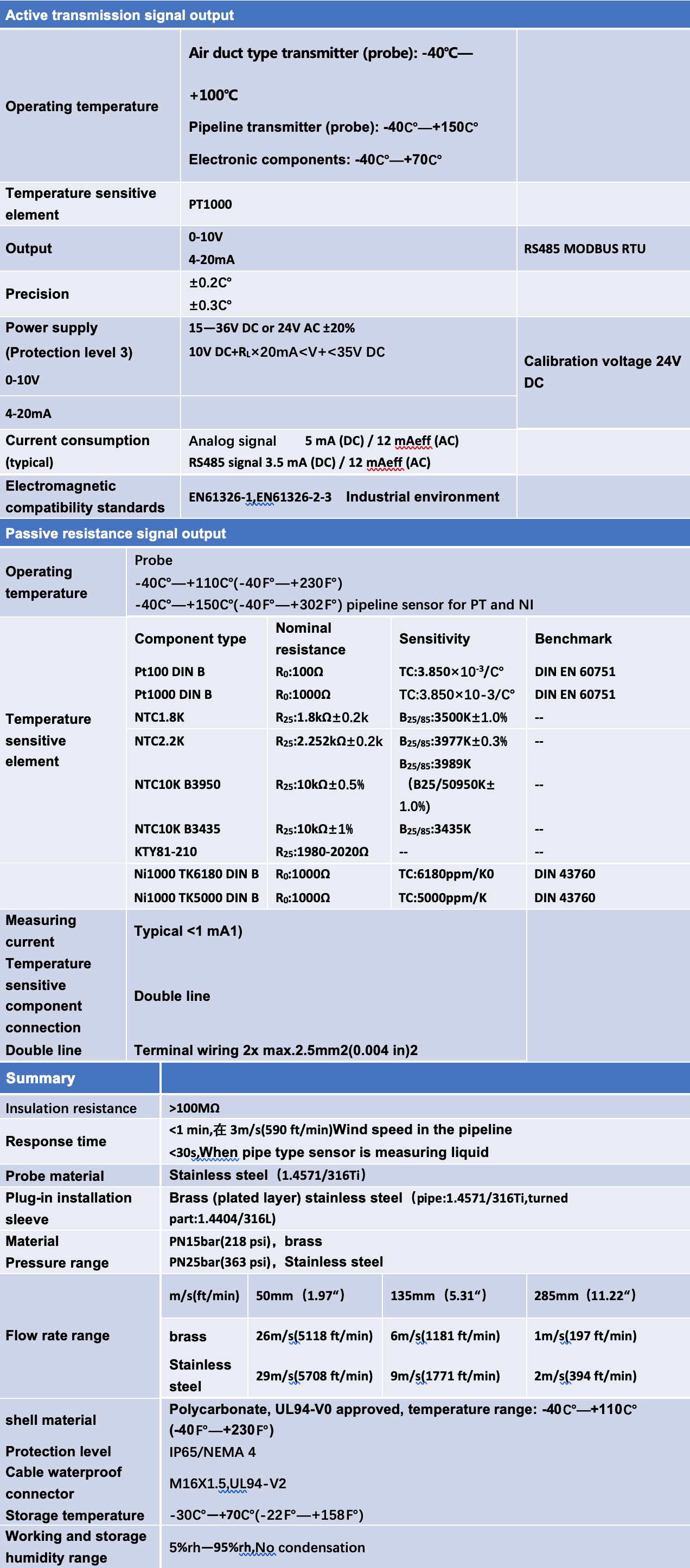

The output signal of the transmitter is standard 4-20mA and 0-10V. You can also choose the passive resistance output mode, or the digital signal output mode with RS485 MODBUS RTU. Passive resistance signal output has a variety of different temperature-sensitive components, such as PT1000, NTC10K or Ni1000, etc., for passive temperature output.

With a high IP65 protection level, the innovative installation concept makes the installation of the sensor faster and easier.

Typical application range

Engineering considerations

Cable laying and cable selection:

If the rated pressure exceeds PN10, a stainless steel (V4A) protection tube is required. If necessary, the temperature range is selected according to the sensor.

A safety weak current transformer with a separate circuit is required to supply power to the sensor. When selecting a transformer and protecting it, the local safety standards should be observed.

When choosing the size of the transformer, the power consumption of the sensor must be taken into consideration. Please refer to the sensor technical data for correct wiring of the sensor.

The cable length must be within the allowable range.

When laying cables, it must be noted that the longer the cable laying side by side and the smaller the spacing, the greater the electromagnetic interference.

In environments with EMC problems, shielded protective cables must be used.

Twisted-pair cables must be used for cables that use transformer secondary power supply lines and signal lines.

Installation Precautions

The installation position of the sensor is determined according to the purpose:

• Used for water supply temperature control (heating fluid)

-The pump is connected to the fluid, and the sensor is placed directly behind the pump

-The pump is connected to the backflow, and the sensor is placed 1.5m-2m behind the mixing valve

• Used to limit the return water temperature

The sensor should be installed at the elbow so that the immersion rod or protective bag can face the direction of the fluid, and the fluid at the temperature measurement site must be fully mixed. If the pump is connected to return water, the temperature measurement point must be downstream of the pump and at least 1.5m away from the mixing point

The sensor should be installed in a place where the signal line does not enter from the top.

For all types of sensors, the immersion length is at least 60mm.

The sensor cannot be covered by the bonding material.

When installing the sensor, the threaded short joint or T-joint (G ½) should be welded to the pipe.

Dimensions